Domestic Supply Chains: The Economic Engine Behind US Manufacturing

If we don’t build our energy infrastructure here, someone somewhere else will.

By Mike Koralewski, Chief Supply Chain Officer, First Solar

American manufacturing powers our nation. Behind every product, every innovation, and every job is a network of supply chains that make it all possible. They ensure that when America needs to lead, America can deliver.

As one of the world’s largest solar panel manufacturers and one of the only headquartered in the United States, First Solar is constantly working to ensure American energy dominance. Every panel we manufacture in the US relies on a foundation of American suppliers. In an era where global disruptions can halt progress overnight, building resilient domestic supply chains isn’t just smart — it’s essential.

American manufacturing has always been close to my heart. Growing up in Toledo, Ohio —a community with a long history as a hub for the glass industry — I developed an early appreciation for what American manufacturing means. I remember visiting steel mills in Pennsylvania as a kid, seeing first-hand the strength of an industry that built this country. Those experiences shaped my belief that manufacturing matters — for jobs, for economic stability, and for national security.

Today, in my role at First Solar, I’m proud to be part of a team that’s working to secure America’s energy future. We’ve built a business model that sets us apart from the Chinese companies that dominate the utility-scale solar industry: US manufacturing backed by a domestic supply chain.

Why domestic supply chains matter

When I think about why a domestic supply chain is important, I go back to a simple analogy: the neighborhood grocery store. You want your store close to home because you want reliable, readily available products. You know that when you need a gallon of milk, it’ll be there — not spoiled and not from a questionable source. Solar technology manufacturing works much the same way. It isn’t just about convenience — it’s about resilience and reliability.

A domestic supply chain allows us to anticipate needs and mitigate logistics challenges. Moving goods 100 miles by truck is vastly different from moving them 3,000 miles by sea. It’s faster, cheaper, and far more predictable. It also lowers carbon emissions. By building and sourcing locally, we cut transportation emissions and align our operations with our commitment to operate responsibly.

Domestic manufacturing and domestic supply chains offer risk mitigation. They provide shields against tariffs, geopolitical tensions, and overseas disruptions. They lower costs and enable us to respond quickly when demand spikes. Together, they help ensure a level playing field and protect American jobs from unfair trade practices.

Building up communities alongside supply chains

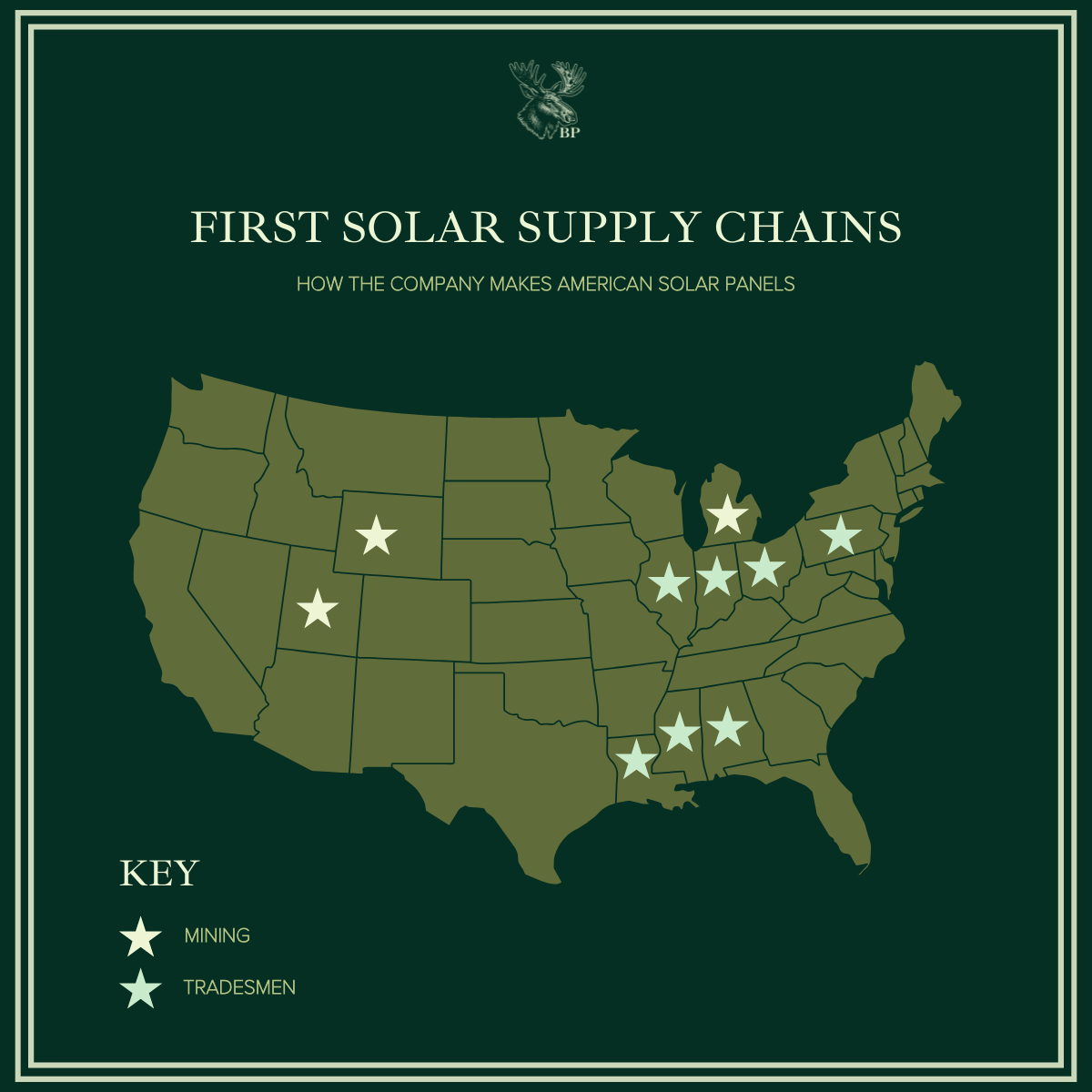

First Solar’s domestic supply chain is deep and diverse. By sourcing our materials in the US, we support the employment of thousands of hardworking people across the country. This includes soda ash miners in Wyoming; silica miners in Michigan; copper miners in Utah; steel workers in Alabama, Louisiana, Mississippi, and Ohio; glass workers in Illinois, Ohio, and Pennsylvania; woodworkers in Indiana; and a nationwide network of truckers, railroad workers, and many others. It runs the gamut from large public companies to small local businesses. From high-tech semiconductor manufacturers to family-owned pallet makers, every link in our supply chain contributes to America’s energy future.

Wherever possible, we work to localize our supply chains. For example, our steel value chain is located within a 100-mile radius of our Ohio manufacturing campus. In Alabama, our entire steel supply chain is located within a 25-mile radius of our manufacturing facility.

Our approach is rooted in collaboration. Working with suppliers who live in our communities fosters trust and problem-solving. When I see partners like Nagel Trucking or ICE Industries thriving alongside us, it’s gratifying to know they’ve been able to grow because of what we’re doing together.

Shared success enables mutual growth. Supporting First Solar’s demand enables our suppliers to invest in their own capacity expansion. Take the glass manufacturing industry, for example. We’ve helped restart shuttered float glass lines with our partner Vitro Architectural Glass in Pennsylvania and built new float glass lines dedicated to solar with NSG Group in Ohio. First Solar currently uses about 15% of US float glass capacity, and as we’ve grown so have our partners in the glass industry.

There’s another advantage to domestic supply chains: alignment. When you work with suppliers in your own community, you share common goals. We all need skilled people, raw materials, transportation, and supportive policies. That mutual dependence fosters collaboration. It also creates good jobs that elevate lives and strengthens communities, giving American workers the opportunity to invest in their futures without having to move away from their home communities.

In Louisiana, for example, our investment in a manufacturing facility in Iberia Parish jump-started industrial growth in a region that had never hosted large-scale manufacturing. In Alabama, we revitalized a rural community outside Huntsville. When you put money in people’s pockets, it circulates through the local economy, creating opportunities for individuals, a higher quality of life for families, and prosperity for communities.

Every US factory we’ve built represents a billion-dollar investment and employs 800+ people. And opportunity comes not just from our jobs, but also the jobs we support with our suppliers and contractors. For every direct job at First Solar, it is estimated that 7.3 more indirect and induced jobs are supported. The economic benefits of all those jobs ripple outward, bringing money into shops, restaurants, schools, and businesses throughout the community. By 2026, it is projected that we will support more than 30,000 indirect and induced jobs and inject about $5 billion into the US economy. That’s the multiplier effect of US manufacturing and US supply chains. That’s what building and sourcing in America looks like.

The promise of American supply chains

At First Solar, we believe that American manufacturing and American supply chains are essential for our nation’s long-term energy security. If we don’t build our energy infrastructure here, someone somewhere else will and we risk becoming dependent on foreign governments for the energy that drives our nation. That’s not acceptable. We need to control our own energy future.

By developing a domestic supply chain, we’re not only working to secure American energy independence, we’re creating jobs, investing in communities, and laying the groundwork for an American manufacturing renaissance. For us, it isn’t just about making solar panels. It’s about ensuring that when America needs energy, America can deliver.

Domestic supply chains are integral to the success of American manufacturing. They connect industries, businesses, communities, and people in a shared mission: powering a bright future for America.

Michael Koralewski was appointed Chief Supply Chain Officer in November 2022 and is accountable for maintaining executive oversight of First Solar’s strategic global supply chain. Learn more about First Solar.

A good read.